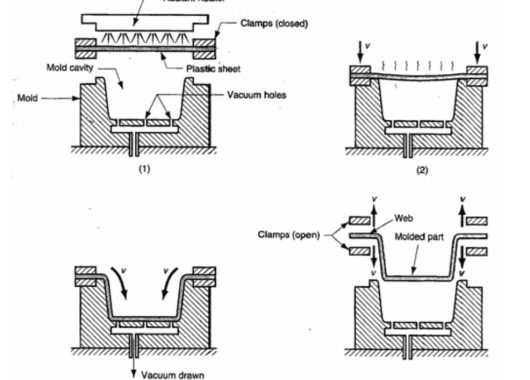

Heating the Material: Once the polycarbonate sheet is dry, it is heated to its thermoforming temperature. Uniform heating is essential to achieve a consistent and high-quality final product. The heating temperature varies depending on the polycarbonate material and thickness.

Forming the Material: When the plastic sheet reaches the appropriate thermoforming temperature, it is placed onto a mold. Then, vacuum pressure is applied to shape the plastic sheet according to the desired form.

Cooling: After the plexiglass sheet conforms to the mold, it is cooled to solidify and retain its new shape. The cooling process must be controlled to optimize the final product quality and minimize stress or warping.

Trimming and Finishing: Once the formed polycarbonate sheet has cooled, we use 3-axis or 5-axis CNC trimming or laser cutting to refine the shape.

![Pressure Thermoforming]()

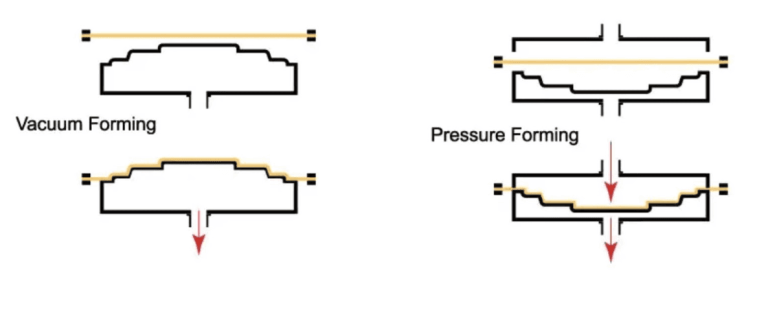

Pressure Thermoforming

Heating: First, the thermoplastic sheet is heated to a specific temperature, typically just below the melting point of polycarbonate. This process softens the material, making it more flexible and easier to shape.

Forming: Once heated, the sheet is placed onto a mold or tool designed to shape the final product. A combination of vacuum and pressure is applied to the sheet. The vacuum helps pull the sheet tightly against the mold to maintain its shape, while pressure (through air or mechanical means) is used to press the material into complex details and fine features of the mold.

Cooling: After the thermoplastic material takes the shape of the mold, it is rapidly cooled. This cooling process solidifies the material, ensuring it retains the desired shape when removed from the mold.

Trimming: Once cooled, the excess material (called "flash") is trimmed or cut away, leaving a finished product.

Pressure thermoforming is used to produce a wide range of products, from simple packaging trays to more complex items such as automotive components, aircraft interior parts, and medical device enclosures. This process is often chosen for its ability to produce parts with excellent detail and surface finish, making it a cost-effective alternative for manufacturing complex designs with aesthetic appeal. Additionally, it is suitable for both small and large production runs, offering flexibility in production volumes.

2. Benefits and Applications of Both Techniques

Vacuum Thermoforming

Benefits:

- Creates a variety of irregular shapes and is suitable for automated and mechanical packaging, reducing labor costs.

- Low mold processing costs.

- Short production time and high manufacturing efficiency.

- No emissions, wastewater, or waste production, meeting environmental standards.

Applications:

- Polycarbonate kayaks

- Polycarbonate igloos

- Polycarbonate suitcases

- Police riot shields

- Machine guards

- Boat windshields

- Polycarbonate windshields

Pressure Thermoforming

Benefits:

- Pressure-assisted forming creates highly detailed parts, often resembling injection-molded components.

- Thermoforming mold costs are lower than injection molding.

- Shorter mold lead time compared to injection molding.

- Suitable for smaller production volumes than injection molding.

Applications:

- Automotive parts

- Lightweight enclosures

- Machine guards

- POP displays & kiosks

- Helmet visors

3 Conclusion

Thermoforming combined with polycarbonate sheets is a modern and efficient manufacturing process. This method provides numerous benefits across various industries. It is not just a processing technique but also a comprehensive solution that optimizes multiple aspects of production.

This process enables mass production with high precision, reducing waste and optimizing labor costs. Thermoforming allows for the creation of complex and aesthetically appealing products that meet high market demands. It ensures both visual appeal and added product value.

At Green Roofing, we not only provide processing services but also work closely with our clients to consult and implement the most suitable manufacturing solutions. Our team of experts is committed to delivering outstanding value through advanced Thermoforming technology.

📞 Contact us today for a detailed quote and expert consultation!

GREEN ROOFING CO., LTD

--------------------------------------------------

Hotline: 0932 06 6699 - (028) 6681 7799

Email: info@greenroofing.vn

Website: https://www.greenroofing.vn/