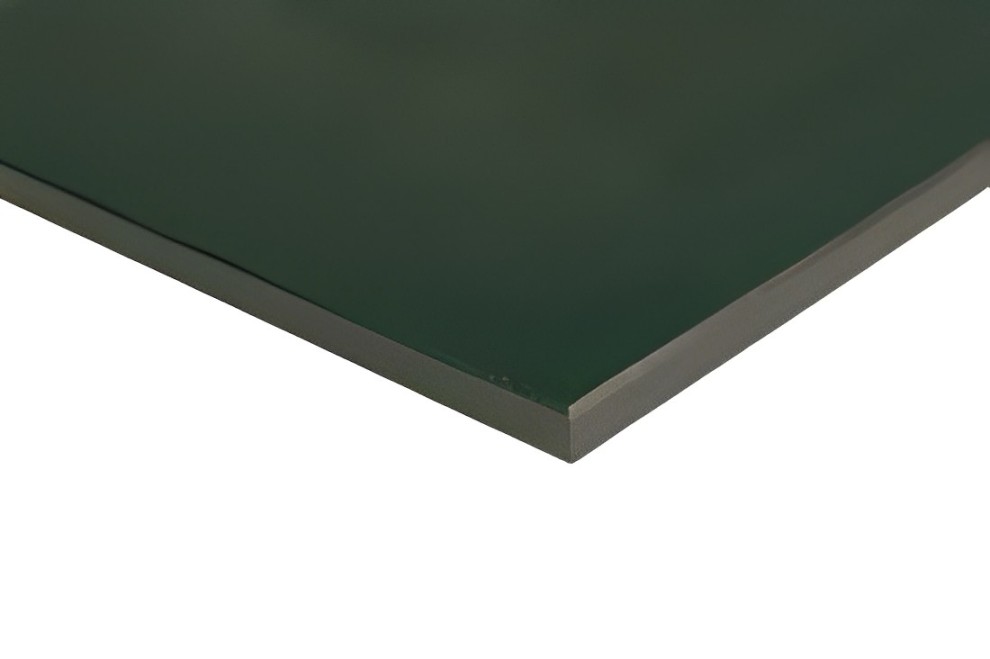

1. ESD POM

ESD POM (Polyoxymethylene) is suitable for manual production operations, preventing electrostatic discharge (ESD) when handling components and electronic parts. It is ideal for clamps used in rubber chip manufacturing or sensitive electronic component production, including hard disks and printed circuit boards (PCBs).

Properties:

- Surface resistivity: 10⁶ – 10⁸ Ω/sq

- Maximum operating temperature: 107°C

- High mechanical strength and wear resistance

- Good dimensional stability

- Easy to machine

Applications:

POM is used for chip socket connectors to prevent ESD damage on conveyor belt equipment, helping to protect thousands of chips annually; Components and parts in semiconductor manufacturing, LCD devices; Components of semiconductor testing equipment; Electronic components, etc.

2. ESD PAI

ESD PAI (Polyamide-imide) is an advanced anti-static plastic with excellent impact resistance and high-temperature endurance. It is an ideal dielectric material for semiconductor manufacturing, test sockets, and conveyor systems due to its unique ability to withstand dielectric breakdown under high voltage (>100V). Unlike conventional carbon-fiber-reinforced materials, ESD PAI maintains its dielectric properties even under voltages of 100-1000V while providing superior mechanical performance.

Properties:

- Surface resistivity: 10¹⁰ – 10¹² Ω/sq

- Maximum operating temperature: 250°C

- Excellent dimensional stability

- High mechanical strength

Applications:

Components of production lines, semiconductor parts and LCD devices, components of semiconductor testing equipment, electronic components, molds, and container manufacturing.

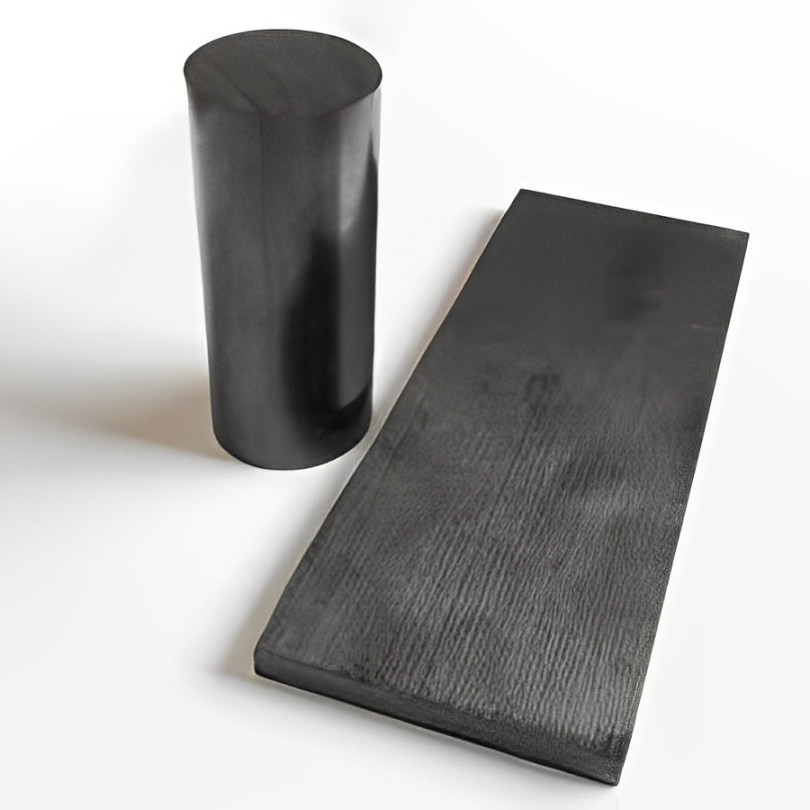

3. ESD PEEK

ESD PEEK (Polyetheretherketone) exhibits excellent electrical insulation and mechanical properties, low moisture absorption, and stable dimensional integrity.

Properties:

- Surface resistivity: 10⁶ – 10¹¹ Ω/sq

- High wear resistance

- Strong mechanical properties

Applications:

Components and parts of production lines; semiconductor parts; LCD devices; components of semiconductor testing equipment; electrical equipment; molds and container manufacturing equipment.

4. ESD PEI

ESD PEI (Polyetherimide) offers excellent mechanical properties and withstands high operating temperatures of up to 220°C. It provides a reliable anti-static solution for high-temperature environments while maintaining dimensional stability due to its low thermal expansion coefficient and minimal water absorption. It is an ideal material for transportation equipment, the electronics industry, and semiconductor applications.

Properties:

- Surface resistivity: 10⁴ – 10⁹ Ω/sq

- Maximum operating temperature: 200°C

- Low internal stress, suitable for high-precision machinery

- High mechanical strength, rigidity, and impact resistance

Applications:

Chip socket connectors, directional valves, transportation equipment, protective devices, cleanroom padding. Additionally, anti-static PEI is also used for components and equipment in production lines, automotive manufacturing, medical devices, food processing, and packaging.

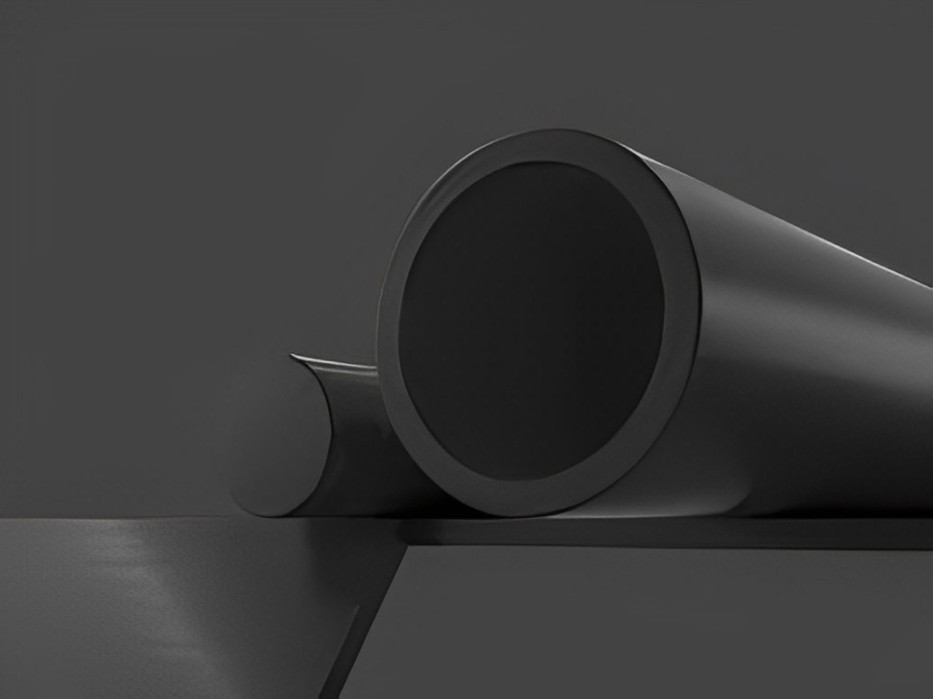

5. ESD PTFE

ESD PTFE (Polytetrafluoroethylene) is reinforced with synthetic mica, offering exceptional low-friction, dimensional stability, and anti-static properties. It addresses the electrostatic discharge issue of pure PTFE while retaining its unique chemical resistance.

Properties:

- Surface resistivity: 10¹⁰ – 10¹² Ω/sq

- Maximum operating temperature: 260°C

- Excellent thermal insulation

- Low friction coefficient

- Exceptional chemical resistance (virtually unreactive to any chemical)

Applications:

Used for components of production lines, semiconductor parts, LCD devices, components of semiconductor testing equipment, electronic equipment; molds and container fabrication; gears, spiral rings, sliding bearings, bushings, etc.

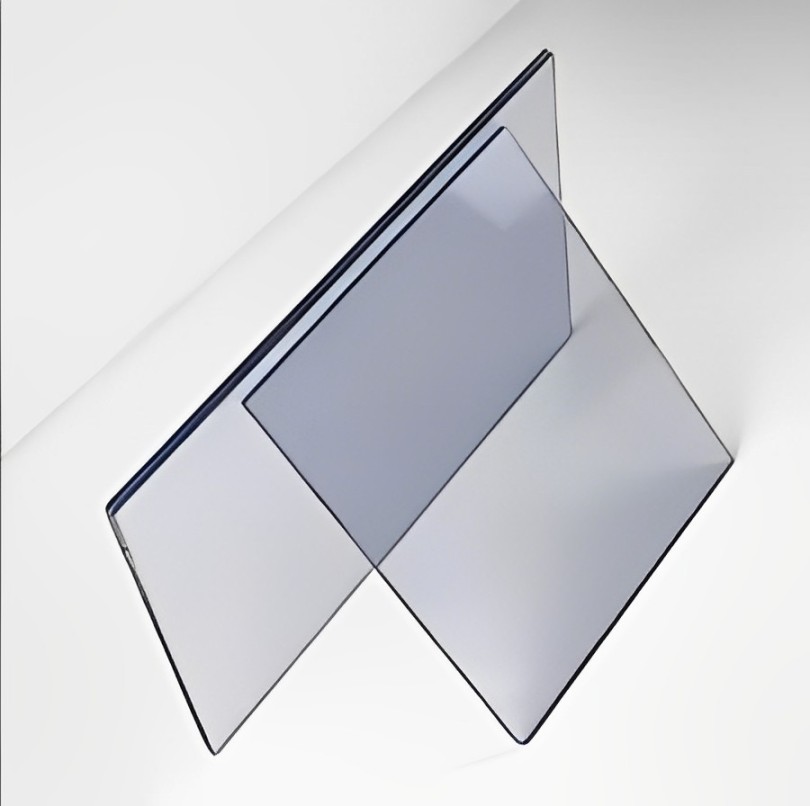

6. ESD PVC

ESD PVC (Transparent anti-static PVC) utilizes advanced surface coating technology to provide effective wear resistance, flame retardancy, and anti-static properties.

Properties:

- Superior chemical resistance

- Impact-resistant surface

- High surface hardness and scratch resistance

- Flame retardant (UL-94, V0 standard)

Applications:

Shielding equipment, cleanroom equipment, laboratory devices, chemical storage containers. Additionally, anti-static PVC is also used in electroplating, chemical processing, and electronics industries.